BABA ELECTROPLATERS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to BABA ELECTROPLATERS

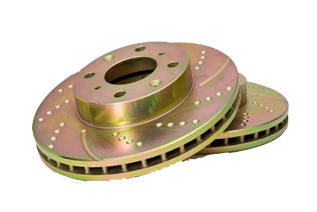

Zinc Cobalt Electroplating

Zinc-cobalt is one of the alloy plating processes developed in the nineties to replace cadmium and to provide enhanced corrosion resistance. It has greater corrosion resistance than zinc. In salt spray testing the coating will achieve in the range of 500 hours to red rust. Zinc-cobalt like zinc can be combined with chromates and sealers to increase corrosion resistance and improve the appearance. Current method of application at hohman plating is barrel plating.

Features & Advantages

Enhances corrosion resttance compared with zinc for the same thickness

Uniform ductility

Alternative procees for hazardus cadmium plating

Six times more corrosion resistance

Cobalt content in coating 0.2 – 0.8 % by weight

Over 400 hrs + nss

Availabel Process Type

Vat (or) rack process

Barrel process

Supplimentary Treatments Colored Conversion Treatment

Hexavalent black (cr 6+) & trivalent black (cr3+)

Hexavalent yellow (cr 6+) & trivalent yellow (cr 3+)

Hexavalent clear to blue (cr 6+) & trivalent clear to blue (cr 3+)

Hexavalent green

Industry Standards

ASTM B840

ASTM B633

ASTM B117

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.